Kiski Precision Expands Contract Manufacturing Ability with New Assembly & Wiring Services

What started out as one person making magnet tracks in 2018 has today grown into a new, comprehensive Assembly and Wiring service with eight employees – and officials of Kiski Precision Industries say it is already creating benefits for their customers by saving time and money.

Assembly services are not new for the 22-year-old company. Seal assemblies have been performed for more than a decade. Casting assemblies have been done for over 15 years. But Dave Holm, KPI’s president, said adding a dedicated assembly and wiring operation to the company’s engineering and other services roster positions KPI as a one-stop-shop contract manufacturer.

“This was a big business decision, but we believed this expansion would maximize value for the customer, so we committed to establishing the best wiring and assembly service available.”

KPI is an industrial services company that offers a host of value-added services. Relying equally on technology and human performance, KPI works from state-of-the-art equipment that is managed by veteran craftsmen who combine for hundreds of years of experience.

“We are always evaluating and adopting new measures to further advance our performance, or adding new equipment and processes for faster turnaround, which saves the customer time and money,” Holm said. “Adding assembly and wiring was a logical expansion.”

The Assembly and Wiring facility is a climate-controlled building, separate from the machining and welding areas. It houses assembly benches, storage shelves, tooling, and packaging equipment to support high-volume production of component and sub-system assemblies, and system-level assemblies requiring electrical, mechanical, or fluid integration. Holm noted that KPI also designs and manufactures custom assembly fixtures for contract manufacturing clients.

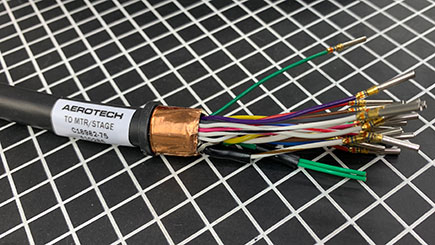

Equipment includes customer-specific product stations for prepping, gluing, and assembly; wire assembly stations with stripping soldering, crimping, wire, and cable harnessing; and testing capabilities. Assembly stations are fully equipped for custom mechanical assembly of all shapes and sizes.

Wiring projects include complete electrical control panel assembly, chassis wiring, custom cabling, and cable harnesses to support electrical components like motors, hydraulic assemblies, sensors, instrumentation, and customized machine cables. The area includes automated testing equipment to ensure accuracy and efficiency. Future expansion of this service includes integrating PLC or motion controllers into an enclosure along with the additional peripheral electronics, such as relays, drives, and power supplies.

Integrated Systems capabilities include pneumatic or hydraulic actuation, electromechanical motors and actuators, control panels, machine controllers, electrical or fluid power wiring and plumbing, machine frames and safety. KPI has also recently designed and assembled laser light safe enclosures for both in-house use in the welding area, and for customer use.

Why Offering an Assembly and Wiring Service Matters

Time and money. And peace of mind.

If a company does not possess the in-house expertise to complete the task, outsourcing to KPI removes the burden of recruiting and training new talent. Also, costs in production builds can vary, so outsourcing puts the supply chain obligation on KPI.

“A good contract manufacturer has the ability to gain an understanding of the customer’s needs and then work with them to set up an application that ultimately saves them time and money,” Holm said.

KPI’s Assembly and Wiring facility is humming with projects at various stages. Customer lead times are a priority to ensure timely delivery on the contract. Employees continue to hone skills and gain certifications and higher-end credentials. Completed projects are heading out the door to happy customers.

“We have seen a variety of assembly requirements over the years. From electric motor component production builds to polishing machinery to hydraulic pump and valve systems,” Holm said. “Almost any industry could make use of our assembly and wiring services or any of our contract manufacturing abilities.”