Welded Machine Bases

Engineered for Strength.

Built for Precision

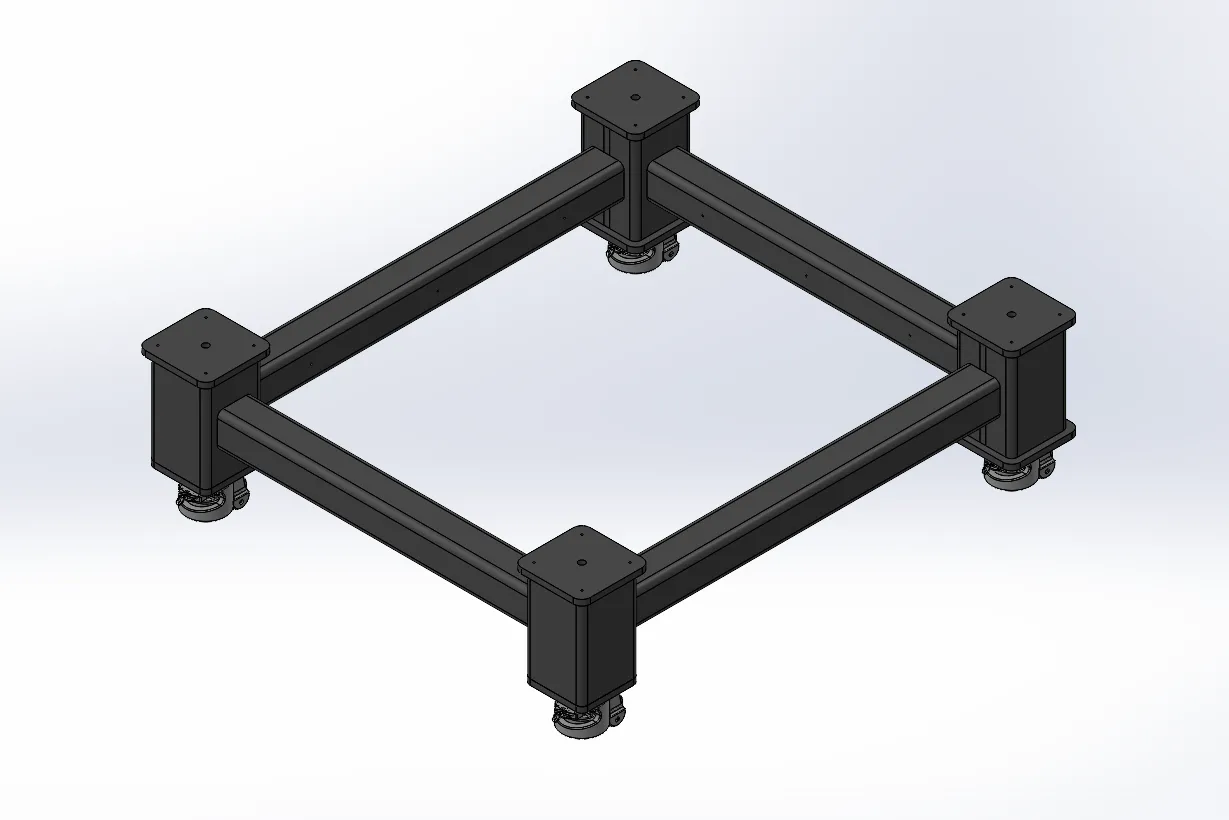

Kiski Precision Welded Machine Bases are built to perform and crafted with care to be the foundational show piece of your end product. Available in Standard, Advanced, and Custom configurations, each base is designed for durability, accuracy, and seamless integration into your products and operations.

Standard WMB

Our Standard Welded Machine Bases are pre-engineered and ready to perform. Configurable with 3×3 or 4×4 steel tubing, a durable powder coat finish, and various tabletop options, these units offer a dependable solution for machine support. They can feature foot pads, casters, levelers or both, along with an optional shelf, and forklift access holes.

Advanced WMB

The Advanced model includes all the performance and structure of the Standard but allows for the addition of side panels or doors. Choose between any combination of panels or doors commonly used to enclose electronics in the base. Optional ventilation grilles are also available. Designed to fit your exact setup while staying within proven engineering standards.

Custom WMB

When pre-engineered options aren’t enough, our Custom Welded Machine Bases offer complete design flexibility. Whether you’re working with oversized equipment, unique mounting requirements, or need specialized hole patterns or materials, we’ll engineer a custom base built to your exact specifications. This level of customization includes engineering support and full collaboration.

specs and options

- Design Features

- Pre-engineered sizes to meet most applications

- Optional table top choices to best suit your needs

- Choose different feet options for you application

- Solutions that support loads from a few thousand pounds to over 20,000 lbs

- Key Applications

- Automated inspection systems

- Pick and place applications

- Machine tools

- Any manufacturing process where a structurally rigid base is needed

- Rugged and Reliable Construction

- Two different steel tube sizes available

- Durable powder coat finish

- Aesthetically pleasing result to support all high end applications

WMB Weight Examples

The exact weight of your Welded Machine Base will be determined by your configuration. Below are examples of our upper and lower limits to ensure you have the right equipment to move your new Machine Base where you need it.

| Description |

Approximate Weight (lbs)

|

|---|---|

| Smallest WMB with no tabletop | 265 |

| Largest WMB with no tabletop | 900 |

| Smallest WMB with tabletop | 500 |

| Largest WMB with tabletop | 4000 |

Standard Options

| Width (in) | Depth (in) | Height (in) |

|---|---|---|

| 24 | 24 | 24 |

| 30 | 30 | 26 |

| 36 | 36 | 28 |

| 42 | 42 | 30 |

| 48 | 48 | 36 |

| 54 | 54 | |

| 60 | 60 | |

| 66 | 66 | |

| 72 | ||

| 78 |

| Tabletop | Tabletop Thickness (in) | Tabletop Material | Tabletop Finish | Tabletop Plating Finish | Tabletop Attachment |

|---|---|---|---|---|---|

| Yes | 0.63 | Steel | Blanchard Ground | Anodized (Aluminum Only) | Bolted |

| No | 0.75 | Aluminum | Machine Finish | Hardcoat (Aluminum Only) | Welded |

| 1.00 | Stainless Steel | Black Oxide (Steel Only) | Passive Isolation | ||

| 1.25 | Flash Chrome (Steel Only) | ||||

| 1.50 | No Plating | ||||

| 2.00 |

| Feet | Tubing Options | Shelf | Forklift Access Holes |

|---|---|---|---|

| Casters | 3x3x0.25″ | Yes | Yes |

| Levelers | 4x4x0.375″ | No | No |

| Casters & Levelers | |||

| Levelers w/ Vibration Dampening | |||

| Foot Pads |

Advanced Options

Advanced options contain all of the Standard Options listed above with the addition of being able to select doors, panels or both for your machine base. This allows for your base to hide electronics or other related devices. Panels are only available up to 48″ in length. Should you need panels on a WMB larger than 48″ in length, we can offer a Custom model where you can choose how to configure multiple panels to cover sides longer than 48″ in length.

If you choose 2 doors you can choose location options of front and back or left and right.

| Panels | Number of Doors | Door Location | Panels/Doors Mtl | Ventillation Grille |

|---|---|---|---|---|

| Yes | 0 | Front | Steel | None |

| No | 1 | Back | Aluminum | Front/Back |

| 2 | Left | |||

| Right |

Custom Options

If the standard or advanced options do not meet your needs we can help you customize a Standard or Advanced WMB. In this scenario you can work with one of our experts to help you craft the solution you need to meet your application. Customizing a WMB can be a budget friendly way to get exactly what your applications needs.

Should you need a complete custom design to meet your application we can certainly do that as well. See our “Custom Enclosures”.

Need help deciding which WMB is right for your operation? Contact our team to start the conversation.