Why Kiski Precision

Precision Made, Partnership Driven

Precision Made, Partnership Driven is a philosophy that reflects our commitment to crafting the highest quality components and our dedication to fostering strong, collaborative relationships with our clients. We understand that precision in manufacturing is critical and we also know that the strength of our partnerships drives success.

Our process begins with listening and understanding each client’s unique needs and challenges. This initial step is crucial, as it sets the stage for a project that is tailor-fitted to our clients’ specific objectives. At the heart of our operations lies a dynamic team of experts, united in their passion for excellence and innovation. This team’s expertise extends into each interaction with our clients, ensuring transparent communication, responsiveness, and a shared commitment to achieving outstanding results.

Choosing Kiski Precision Industries means opting for a partner as invested in your success as you are. We go beyond mere transactions to build enduring relationships, grounded in trust, respect, and a mutual drive for excellence. Our promise is simple: to deliver precision-made solutions through partnerships that drive success, project after project. In other words, Precision Made, Partnership Driven.

Contact us to learn why Kiski Precision is Your One Stop Precision Shop

Setting the Standard for Precision Manufacturing

Kiski Precision Industries sets the standard in precision manufacturing, ensuring unparalleled quality and precision in every component we deliver. Our commitment to excellence and innovative solutions elevates the value we bring to every project, exceeding our clients’ expectations with consistency and accuracy.

Collaboration fuels our success. We dive deep into manufacturing challenges alongside our clients, transforming complex ideas into reality through a blend of expertise, creativity, and cutting-edge technology. This partnership approach brings immediate value and also creates long term relationships based on trust and mutual respect.

Responsiveness and reliability are cornerstones of our client successes. We thrive on meeting critical deadlines and responding swiftly to client needs. Our dedicated team adopts a proactive stance to projects, focused on timely delivery without compromising quality.

Versatility in our capabilities sets us apart. From custom machining to comprehensive electrical assembly, we offer a broad spectrum of manufacturing services under one roof. This one-stop-precision-shop advantage streamlines production processes, enhances efficiency, and ensures consistent quality across all project phases.

Responsiveness and reliability are cornerstones of our client successes. We thrive on meeting critical deadlines and responding swiftly to client needs. Our dedicated team adopts a proactive stance to projects, focused on timely delivery without compromising quality.

Versatility in our capabilities sets us apart. From custom machining to comprehensive electrical assembly, we offer a broad spectrum of manufacturing services under one roof. This one-stop-precision-shop advantage streamlines production processes, enhances efficiency, and ensures consistent quality across all project phases.

Choose Kiski Precision Industries for your manufacturing needs and experience a partnership defined by quality, innovation, and steadfast commitment to excellence.

Kiski In the Community

At Kiski Precision, we believe that investing in the future of our community means investing in education and developing the next generation of skilled workers. Our commitment to supporting local schools and programs reflects our dedication to empowering the next generation to understand the skills needed career in manufacturing.

Our Contributions to the Community:

- Supporting Springdale High School’s BotsIQ Team For the past three years, we’ve proudly sponsored and mentored Springdale High School’s BotsIQ team, helping students engage in real-world problem-solving through robotics competitions.

-

Hosting Manufacturing Education Events: Each year, we open our doors to high school students from various schools in the area, providing them with hands-on learning experiences and introducing them to potential careers in manufacturing.

- Presenting to Kiski Area 7th Graders: Our commitment to education extends to younger students as well. Our CEO, Dave Holm, present to every 7th grader at Kiski Area School District each year, offering early insights into the world of manufacturing and the exciting career paths it offers.

- Advisory Board Member at Lenape Tech: As an active member of the advisory board at Lenape Tech, we collaborate with educators to help shape the curriculum, ensuring that students are well-prepared to meet the demands of today’s manufacturing industry.

If you want to partner with Kiski on a community initiative, please email us at partnership@

Follow Us on Social Media

Our Team

At Kiski Precision Industries, our team is the heart of our mission and the driving force behind our Big Idea, “Precision Made, Partnership Driven.” Each member’s dedication and expertise are crucial to delivering on our promise of excellence and fostering meaningful partnerships.

President and CEO

Dave Holm leads Kiski Precision Industries with a blend of passion for engineering and a hands-on approach that exemplifies the company’s commitment to quality and innovation. As an engineer who thrives on solving complex problems and finding practical solutions, Dave’s leadership style is characterized by his eagerness to dive into the details and his unwavering commitment to excellence. Under his guidance, Kiski has solidified its reputation as a trusted partner in precision manufacturing, continually pushing the boundaries of what’s possible to meet and exceed client expectations. Dave’s vision for Kiski is not just about achieving technical precision but also about building a company culture that values collaboration, continuous improvement, and community engagement.

Ron Smith,

General Manager

Ron Smith serves as the General Manager of Kiski Precision, a role he’s held for over 19 years. With a career spanning more than three decades, Ron has a wealth of experience in manufacturing and production management. Prior to his current role, he was a Production Manager at Accor Tool Enterprises, where he spent 9 years, and also worked as a Roll Grinder at National Roll Co. His career began as a CNC Supervisor at Accor Tool Enterprises, giving him a strong foundation in precision machining and operational leadership.

Customer Service Manager

Randy’s been with Kiski Precision since 2005, bringing decades of hands-on experience in machining and customer service. He started his career working as a manual and CNC machinist, where he earned his Journeyman’s papers and built the foundation of his expertise.

When Randy joined Kiski, he jumped right into the role of CNC Machinist and Programmer. His skill and attention to detail quickly moved him into a leadership role as CNC Department Lead. For Randy, it’s all about delivering top-notch work and making sure the job’s done right the first time.

In 2021, Randy made the shift into sales and customer service, where he now oversees customer relations. His down-to-earth approach and commitment to service means that clients always know they’re in good hands. Randy’s focus on responsiveness and precision ensures that every customer gets the personalized attention they need, and he’s always ready to do whatever it takes to keep projects on track.

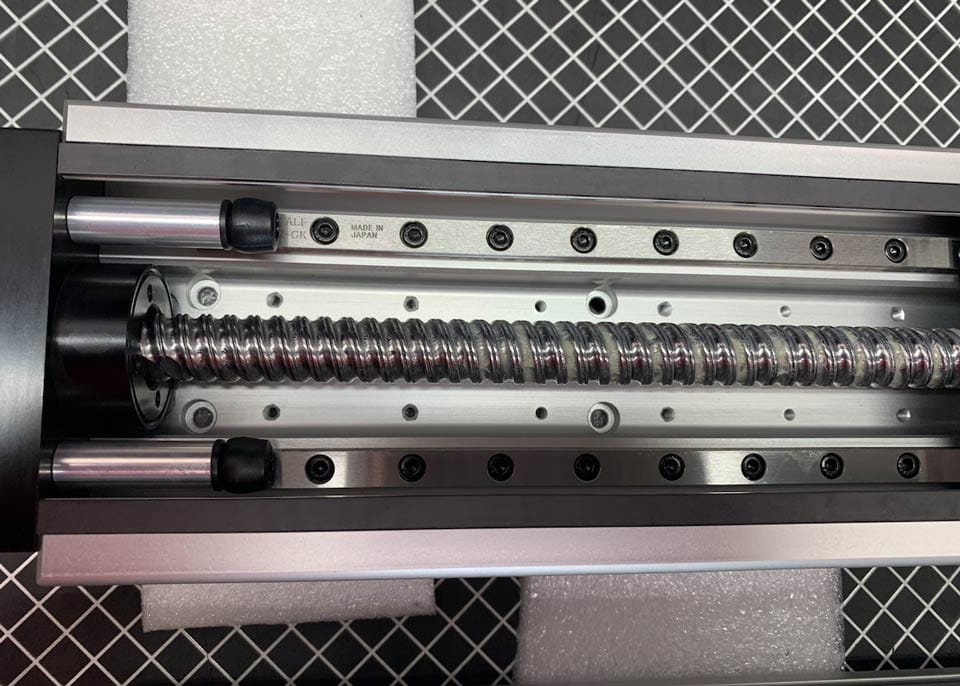

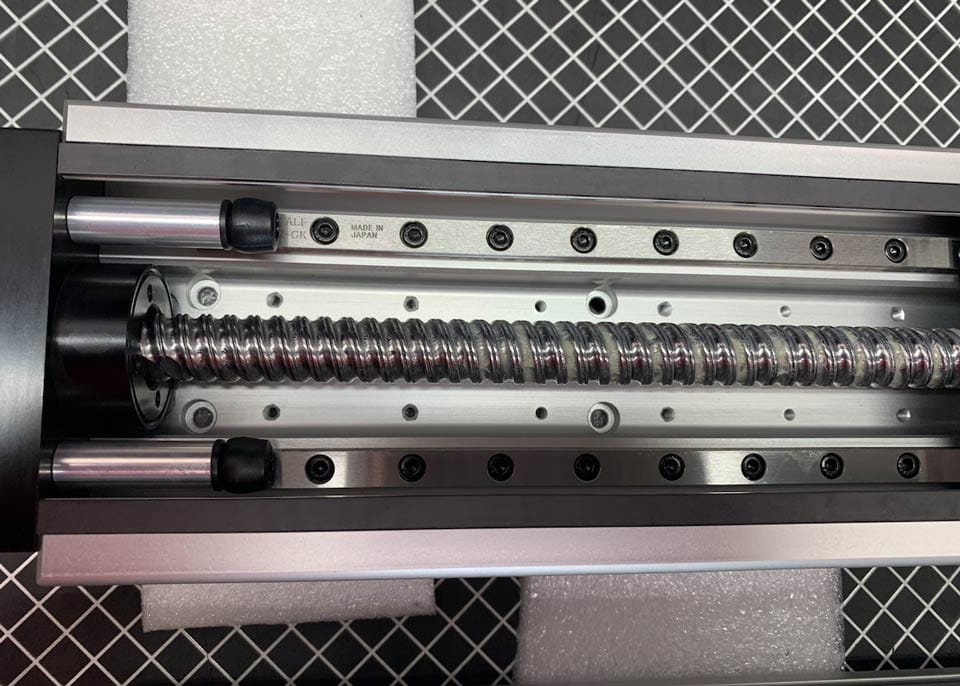

Facilities

At Kiski Precision Industries, our state-of-the-art facilities are at the core of our commitment to excellence. Spanning a significant footprint equipped with the latest in precision manufacturing technology, our workspace is designed to foster innovation, efficiency, and the highest standards of quality. Each area of our facility, from machining centers to assembly lines, is meticulously organized to support our team’s ability to produce complex components with unparalleled precision.

Our facilities are built to encourage collaboration among our team members. Our open spaces encourage brainstorming and problem-solving, bringing together a variety of perspectives and expertise to benefit every project. This collaborative environment is pivotal to our approach, enabling us to tackle the most challenging manufacturing projects and deliver custom solutions that meet our clients’ exacting needs. At Kiski Precision, our facilities are the foundation upon which we build our reputation for excellence and innovation in the manufacturing industry.

Kiski Precision’s campus features four buildings with a total of 85,000 square feet of manufacturing space. Building 1 houses our machining and welding operations, spanning 35,000 square feet and equipped with a 10-ton crane that covers the entire length of the facility. Building 2 contains our temperature-controlled precision assembly area, wiring, and grinding services. Building 3 is dedicated to our EDM operations, with additional space for future expansion. Each building includes dedicated quality control areas to ensure the highest standards.